Combining Weathering and Mechanical Test Methods to Quantify Long-Term Material Durability

- mvermeulen89

- Aug 25, 2025

- 4 min read

Updated: Aug 26, 2025

Introduction

Product longevity, both mechanical or cosmetic, depends selecting materials that can withstand real-world conditions over the life of the product. At Assured Testing Services, we help manufacturers qualify materials using a variety of methods, including weathering tests such as UV or xenon arc exposure. These tests provide an accelerated means by which materials can be evaluated for mechanical and cosmetic performance when exposed conditions that mimic sunlight, rain, and fluctuating temperatures. When combined with mechanical durability testing, manufacturers gain a complete picture of material’s long-term performance and product reliability.

What is material durability and why does it matter?

Material durability refers to a material’s ability to maintain key properties such as strength, flexibility, compressibility, abrasion resistance, over its intended service life. When materials succumb to environmental stressors such as UV light, temperature fluctuations or moisture, materials can begin to degrade. They may become brittle, develop cracks or delamination, erode, fade, or show surface changes such as gloss loss, reduced hydrophobicity, or diminished abrasion resistance. These changes not only impact the mechanical performance, but also compromise the appearance of the final product. This can cause premature product failure, safety or compliance issues, and customer dissatisfaction. Manufacturers often use material durability testing in combination with environmental exposure testing to predict how their products will perform after years of exposure to sunlight, heat and moisture.

How Weathering Tests Evaluate Material Durability

The two most common test methods used to simulate sunlight exposure are fluorescent UV testing, and xenon arc testing. Fluorescent UV weathering utilizes lamps which emit short wave UV spectrum light, typically at 340nm or 313nm. These lamps do not produce much visible or infrared light, and tends to accelerate degradation such as polymer breakdown, gloss loss, or surface cracking. Because of the harsher exposure, and lower equipment cost, UV testing is often chosen for comparative studies, or early-stage material screening.

Xenon arc testing on the other hand, utilizes xenon lamps which closely mimic the full spectrum of natural sunlight which includes UV, visible and infrared radiation. With the use of optical filters, xenon arc testing can simulate outdoor sunlight exposure or exposure behind glass. This makes xenon arc testing valuable when realistic simulation of outdoor conditions is required, and it is often used when real-world correlation is critical.

Role of Mechanical Testing to Evaluate Weathering Performance

Visual evaluations of materials exposed to weathering tests like UV and xenon arc provide valuable insight into surface and cosmetic damage such as fading, loss of gloss, or surface cracking. However, these tests do not capture changes in the structural integrity of the material. Mechanical testing methods such as tensile, compression, or abrasion testing quantify how the physical properties of the material were affected by UV or xenon weathering. These mechanical tests can reveal hidden degradation such as embrittlement, reduced elongation, or microcracking that may not be visible on the surface. Combining appearance-based evaluation with quantifiable mechanical testing provides a more complete picture of the properties that contribute to long term material durability.

Examples of materials that Assured Testing Services has

helped their clients evaluate long term durability using a combination of weathering and mechanical testing:

Building materials: Fiber-reinforced wall cladding used for exterior applications was exposed to a combination of freeze thaw and water immersion, then evaluated with compression/deflection testing

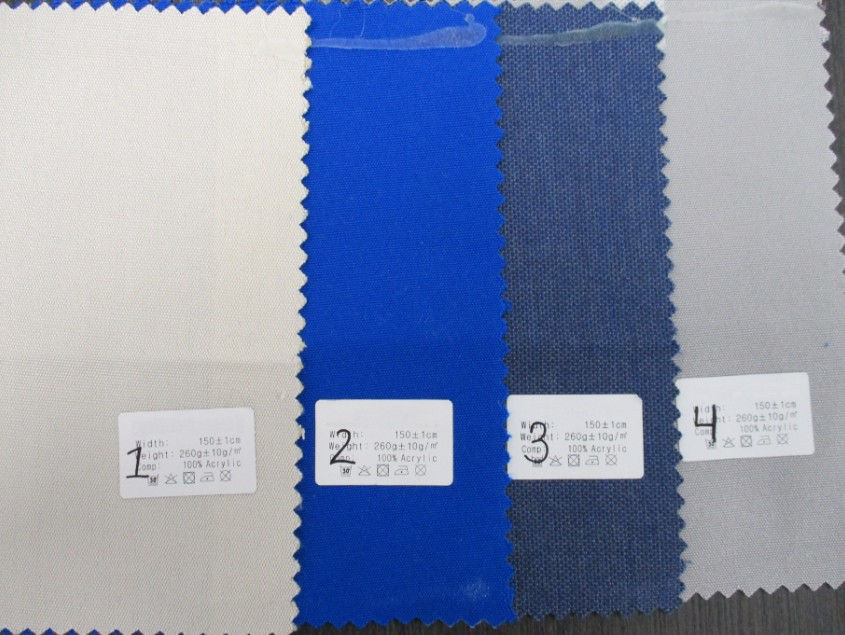

Consumer Goods: Performance textile used for recreational goods underwent xenon arc testing followed by tensile and tongue tear tests

Electronics: Candidate plastic materials for an outdoor electronic enclosure were exposed to fluorescent UV, then tested for tensile strength and elongation to determine long term viability

Some of the common weathering and mechanical test standards we work with:

ASTM D4587 Standard Practice for Fluorescent UV-Condensation Exposures of Paint and Related Coatings

Comments