Water Ingress Testing for Outdoor Electronics: What Manufacturers Need to Know

- mvermeulen89

- Aug 15, 2025

- 5 min read

Introduction

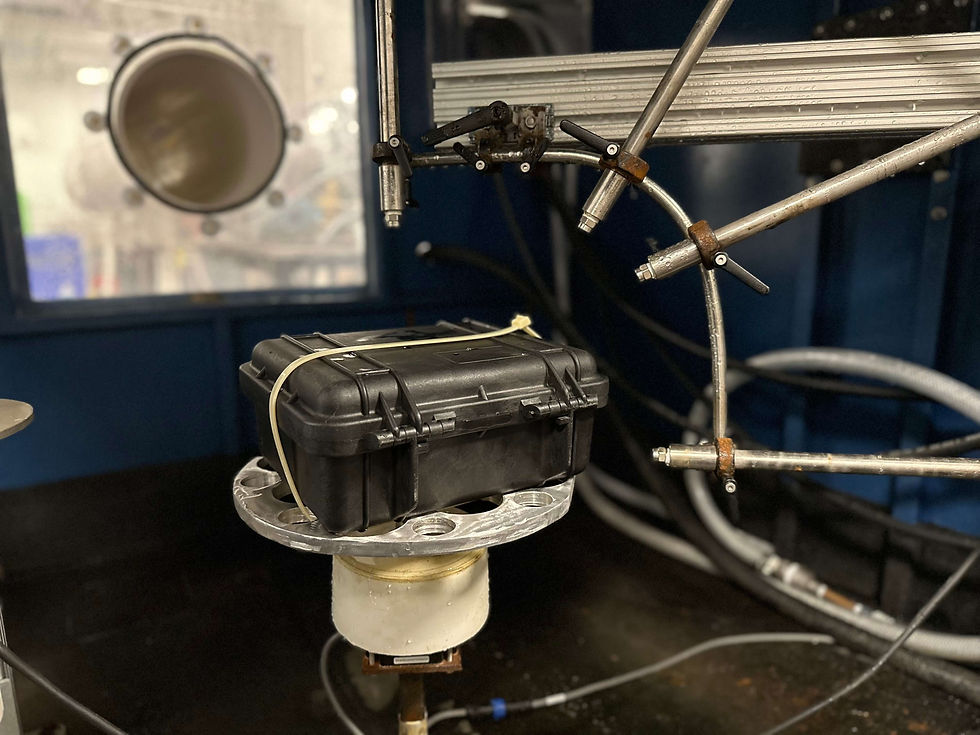

Outdoor electronic devices such as security cameras, lighting, smart entry devices, and

other sensors are becoming increasingly common. The environments that these devices are exposed to in service vary widely. Outdoor electronics can be adversely affected by UV radiation, temperature fluctuations, humidity, chemical exposure, and water intrusion. Water ingress is one of the most common causes of device failure in outdoor electronics. At Assured Testing Services, our water ingress testing services help manufacturers avoid costly failures by validating product performance to standards like IEC 60529 and ISO 20653.

What Is Water Ingress Testing

Water ingress testing involves intentionally exposing devices to water in a way that mimics potential end-use environments. This ranges from rain simulation testing (IPX1

and IPX2) to high-pressure water spray, often at elevated temperatures (IPX6, IPX6K, IPX9K), and even full immersion of a device (IPX7 and IPX9).

There are various test standards used for IP rating testing, with the two most common being IEC 60529: Degrees of Protection Provided by Enclosures (IP Code) and ISO 20653: Road Vehicles – Degrees of Protection (IP Code) – Protection of Electrical Equipment Against Foreign Objects, Water, and Access. These are applied to both industrial and consumer applications and encompass a variety of water ingress tests that help replicate real-world conditions devices may face.

MIL-STD-810 is a U.S. military standard that defines several procedures related to water ingress including rain testing (procedure 506.6), immersion testing (Procedure 512.6) and humidity testing (Procedure 507.6 ). It also includes combined environment testing, which incorporates thermal, humidity, vibration, and altitude stressors into a

single test sequence (Procedure 520.5). It is commonly applied to ruggedized and mission critical equipment such as avionics modules, radomes, vehicle mounted control units, cameras and more.

RTCA DO-160 is another widely used standard that defines a range of environmental testing procedures for airborne equipment. It includes waterproofness testing guidelines specific to the aviation and aerospace industry with procedures that simulate rain, condensation and spray in realistic flight conditions. This helps aviation and aerospace manufacturers ensure their components will perform reliably when in service.

NEMA 250 is another commonly referenced standard that defines electrical enclosure types based on their ability to protect their contents from water, dust and other environmental hazards. Unlike the other IP code, it takes into considerations such as corrosion and mechanical impact. This standard often applies to industrial, utility or outdoor electrical installations.

Why Water Ingress Is a Serious Concern

While other environmental factors can cause cosmetic damage, water ingress is one of the top causes of failure in outdoor electronic devices. This can happen through several mechanisms and cause immediate or long-term damage that ultimately results in failure. Because water is a conductor, it can cause short circuits and electrical failure. It can also block or interfere with sensors such as proximity sensors, light detectors, or capacitive touch surfaces, making a device unresponsive. Over time, even small amounts of water ingress can result in corrosion, mold, or electrochemical migration, which eventually causes failure. Ensuring that devices are properly sealed to withstand the environments in which they are used can prevent these problems.

Common Points of Failure During Ingress Testing

After performing the water spray/application step of the ingress rating test, a thorough

inspection of the device identifies any signs of ingress. At Assured Testing, we strive to provide detailed reports that can help our customers understand potential entry points, design flaws, or defects in the device that may contribute to failure. Some of the common areas of concern are as follows:

Gaskets and Seals:

Incorrect material choice (e.g., a material that is too compressible or loses compression set over time) may provide gaps where water can enter

Degradation from heat, chemical exposure, or UV light can damage gaskets and seals, preventing proper function

Poor fit or improper installation during assembly

Cable and Connector Entry Points

Unsealed connections, commonly USB, RJ45, or coaxial, which are typically designed for indoor use

Poorly fitted grommets or over-molded boots

Wicking through braided or woven cable jackets, or capillary action through multi-layer cable jackets

Vents

Use of non-breathable membrane materials causes moisture to become trapped inside the device; materials must be both breathable and liquid-resistant

Damage to vents from impact or improper maintenance

Poorly functioning vents can cause pressure differentials that lead to seal failure over time

Fastener Holes and Mounting Points:

Cracks formed during installation due to over-tightening, incorrect screw size, or misalignment

Inconsistent torque on closure fasteners that compress only part of a gasket or seal

Lack of washers or seals under fastener heads provides a direct entry point for water

Choosing the Right Rating

A variety of environmental and functional factors influence which water ingress protection rating manufacturers choose when designing their products. Devices that will be outdoors may experience rain (IPX1 and IPX2), blowing dust and sand (IP5X and IP6X), or even complete immersion during flooding (IPX7 and IPX8). Over-engineering for harsh conditions can drive up manufacturing costs and reduce user-friendliness. On the other hand, failing to plan appropriately for harsh conditions may cause premature failure, warranty claims, or customer dissatisfaction.

Manufacturers also need to consider the possible long-term effects of environmental factors such as sunlight, temperature and humidity swings, vibration, and mechanical shock. These can degrade a device’s ability to maintain its ingress rating over time. Additional testing for UV stability, mechanical properties (such as tensile or compressive strength), or corrosion resistance may be needed during device design to select appropriate components.

Key Industries That Require Water Ingress Testing

Manufacturers of various types of devices, enclosures, and components require water

ingress protection rating testing. Industries and devices that Assured Testing Services provides water ingress testing services for include:

Automotive:

Electronic sensors

Lighting modules

Control units

Infotainment systems

Wire harnesses and connectors

Industrial Equipment/Enclosures:

Power supplies and power distribution enclosures

HMIs

PLCs

Motors, drives, and actuators

Lighting

Cameras and vision systems

Outdoor Infrastructure and Utilities:

Telecommunication equipment such as antennas, routers, or base stations

Smart meters

Switches

Cable glands and connectors

Pole-mounted distribution equipment

Consumer Electronics:

Smartphones, e-readers, and tablets

Wearables such as smartwatches and fitness trackers

Smart doorbells and camera systems

Trail cameras, GPS devices, and other recreational products

Portable speakers, headphones, and other audio devices

Do You Need Water Ingress Rating Testing?

Assured Testing Services provides fast, reliable water ingress testing for customers in

many industries. Whether you are developing an industrial device or a consumer product, Assured can assist your company in ensuring it provides adequate water ingress protection.

Common Test Standards

IEC 60529: Degrees of Protection Provided by Enclosures (IP Code)

ISO 20653: Road Vehicles – Degrees of Protection (IP Code) – Protection of Electrical Equipment Against Foreign Objects, Water, and Access

MIL-STD-810 Department of Defense Test Method Standard, Environmental Engineering Considerations and Laboratory Tests

RTCA DO-160 Environmental Conditions and Test Procedures for Airborne Equipment

NEMA 250 Enclosures for Electrical Equipment (1000V Maximum)

Comments